INSTRUNET INTERNAL HARDWARE CALIBRATION

Calibration Overview Calibration involves two different systems:

instruNet Software Calibration Software calibration improves the accuracy of the instruNet voltage measurement and is divided into several components:

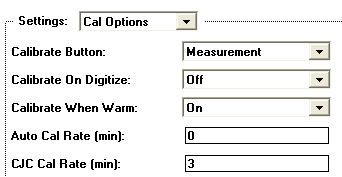

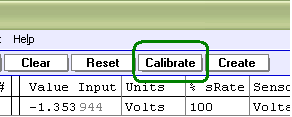

The Full software calibration, which includes all of the above components, occurs when the system is reset (i.e. press RESET button, load .prf configuration file, or start instruNet software), and when the system is Software Calibrated (i.e. press CALIBRATE button, issue software calibrate command, or set up software to auto-calibrate every X minutes). The rate of software auto-calibration is set in the Calibration Options dialog, as described below. Full calibration does not run if digitizing at any sample rate. If digitizing at a fast rate (e.g. > 1Ks/s/sec/ch), then no calibration of any kind occurs. However, if digitizing slowly (e.g. ≤ 1Ks/sec/ch), then the 4 lower items in the above list (e.g. 3.3Vref, Cjc, i100 temp drift) continue to operate. instruNet software contains a Calibration Options dialog that provides several calibration options, as described below. Calibration is helpful at reducing errors that occur when the measurement circuitry internal temperature changes. This dialog, shown below, is accessed by pressing the Setup button in the Record page and then pressing the Calibration button.

Programmatically, one accesses these fields via {netNum=0, devNum =0, modNum=1, chanNum=3, settingGroup = -21 = sgt_CalOptions, fieldNum = 1 to 8 (e.g. 5 = fldNum_CalOptions_CjcCalRate)}. For information on setting these fields programmatically, please see Calibration Routines. For information on setting these with Visual Basic, please click here.

Zero "Calibrate" BUTTON, for Strain Gage & Load Cell Sensors

"Balancing" involves reading the voltage across a sensor and placing it into the "Vinit" field within the Constants settings area. This is done to establish a zero point from the sensor, and should be done when the sensor is not receiving a stimulus (e.g. Load Cell with 0 Kg applied). CALIBRATE ON DIGITIZE CALIBRATE WHEN WARM AUTO CAL RATE (MIN) CJC CAL RATE (MIN) Working With Thermocouple Sensors In order to calculate the temperature of a thermocouple tip, one must know the temperature of the screw terminals that attach the thermocouple wire to the measurement system (e.g. i51x or i100 screw terminals). This is sometimes referred to as "Cold Junction Compensation", "Cjc Calibration", or "Cjc". If at least 1 thermocouple is connected to the system, this Cjc Calibration (i.e. measuring the temperature of the screw terminals) occurs when a Full Calibration occurs (e.g. at the Auto Cal Rate), or when a Cjc Only Calibration occurs (e.g. at the Cjc Cal Rate). CJC CAL RATE (MIN) THERMOCOUPLE DRIFT ERRORS AUTO-CALIBRATE UPON COMMAND ENABLING A BEEP WHEN CALIBRATION OCCURS GETTING ERRADIC READINGS INDEPENDENT OF CALIBRATION SETTINGS?

|

One can remove fixed offset errors from strain gage and load cell sensors using a technique called "balancing". There are two ways to do this -- the easy method described

One can remove fixed offset errors from strain gage and load cell sensors using a technique called "balancing". There are two ways to do this -- the easy method described